What Some Sunscreens Are Hiding…(Republished)

It is summer and it is sunscreen season. Below is an article I recently wrote about the new welcomed changes from the FDA that will force manufacturers to reveal what is in their sunscreens. Please read it and the links to the FDA. This change has go a long way to help save lives through UVA and UVB dangers awareness. Also, since this new regulation, I thought it would be good to reprint the blog article herein. I encourage you to study to protect you and your family.

It is summer and it is sunscreen season. Below is an article I recently wrote about the new welcomed changes from the FDA that will force manufacturers to reveal what is in their sunscreens. Please read it and the links to the FDA. This change has go a long way to help save lives through UVA and UVB dangers awareness. Also, since this new regulation, I thought it would be good to reprint the blog article herein. I encourage you to study to protect you and your family.

My grandfather used to say to me, “make up your mind. Don’t let someone make up your mind for you!” It is more important than ever that you listen to facts based on studies and not opinion.

Original Post Date: July 9, 2009………………….

An open letter to Keys Solar Rx customers from Bob Root, Keys Technologist

Every July, many sunscreen reports are released. Soon after, a number of companies and self-anointed experts try to spread fear, uncertainty and doubt about the use of nano-particles in sunscreens, stating opinion as if it were fact in blog posts and articles. It’s an annual controversy, like clockwork, and this year, as things heat up again, and I am finally breaking my silence.

There are two key issues: a) tests show conclusively that nano-zinc oxide is the best, safest and broadest-range UV protection available, and b) far more sunscreen products use nano-particles than the manufacturers are either aware of or willing to admit. I’ll take each issue in order.

Issue #1: Why, oh why, would you put nano zinc oxide in your sunblock?

Answer: Because at Keys Care, I am trying to save my wife’s life and the lives of countless other melanoma survivors! Simply put, nano zinc oxide has been proven to be the best, safest and broadest range UV protection there is.

Keys manufacturers a moisturizing everyday sunblock with UV protection called Solar Rx. We use uncoated nano-zinc-oxide for a very simple reason: it’s the most effective. We do not hide it, either. It is on the front of every bottle.

For five years, in the face of significant controversy, we have stood our ground, answered questions, and supported our use of nano technology in our moisturizing sunblock. Two years ago, when Consumer Reports Magazine first ranked Keys Solar Rx as the most effective product in its category, a sidebar article talked about nano. The editor wrote,” Keys was the only manufacturers to tell the truth that they use nano-particles.” Now, as more and more scientific proof emerges showing the safety of nano-zinc-oxide, we are adding our voice to the growing support for nano and reiterating that it is more effective than any other form of zinc-oxide.

Nano by Design

When I first developed Solar Rx, I did not just grab some zinc-oxide from a cheap supplier only to later learn that it was based on nano technology. On the contrary, I searched the world to find a nano-zinc-oxide that would deliver the best protection for my wife and best friend, Wendy, who was surgically cured of melanoma skin cancer a decade ago, only to suffer terrible reactions to the chemicals in over-the-counter and prescription sunscreens that her doctors recommended she take. Like transplant patients that must take drugs to avoid rejection, Wendy must employ whatever means possible to avoid UV radiation. Our company was born out of the need for Wendy and I to either find or create a chemical-free solution to her lifelong skin-protection needs. The reactions Wendy was having to popular sunscreens were unbelievable, and we believe they were directly caused by the chemicals in them. I hated seeing her suffer, and knew there had to be a better way. My wife’s comfort, safety and even her life were at stake.

As I searched for answers, I launched a quest to find the most effective ingredients possible for blocking UVA and UVB rays without using questionable chemicals. I wasn’t looking for controversy, or to cut costs or corners. As it turned out, the nano zinc-oxide formulation I found was the most expensive. It also was far more effective than micron- or macro-scale zinc oxide, which is incapable of covering the skin as densely as the smaller, easier-to-compact nano-scale zinc-oxide particles. This is not my opinion, but a fact based on science and the physical properties of the particles.

Zinc-oxide is a physical UV block that has been proven to have the widest range of absorption of UVA, UVB, UVC and soft x-ray. It is a single, non-chemical agent that has been used on the skin for over 100 years in the form of diaper rash ointments, poison ivy lotions and many pharmaceutical treatments. Over 400 peer-reviewed studies show nano-zinc-oxide to be safe, which should remove concerns about absorption into the skin. In fact, the EWG in their 2009 Sunscreen Investigation section entitled “Nanotechnology & Sunscreens” which can be found at (Nanotechnology-Sunscreens) said that they reviewed, “…16 peer-reviewed studies on skin absorption, [and] nearly all showing no absorption of small-scale zinc and titanium sunscreen ingredients through healthy skin. In a 2007 assessment the European Union found no evidence of nano-scale particles absorbing through pig skin, healthy human skin, or the skin of patients suffering from skin disorders (NanoDerm 2007).”

The EWG also applauded the use of zinc and titanium products for reducing “..risks for UVA-induced skin damage, premature aging, wrinkling, and UV-induced immune system damage.” They also said, “The easy way out of the nano debate would be to steer people clear of zinc and titanium sunscreens with a call for more data. In the process such a position would implicitly recommend sunscreen ingredients that don’t work, that break down soon after they are applied, that offer only marginal UVA protection, or that absorb through the skin.”

As a sunblock formulator and designer, I rank safety and efficacy among my critical concerns. I have personally studied this subject for over five years and am privileged to have access to systems, instruments, testing and research from nationally recognized labs, universities and international experts. Research has already shown nano-zinc-oxide to be safe, and ongoing analysis continues to prove how much more effective it is than other chemical-based and physical blocks. Why? Simple physics: smaller is better when it comes to formulating lotions that deliver dense coverage. Nano-zinc-oxide is more effective than micron-sized particles because they are 1000 times smaller, and therefore can be compacted much more densely and arranged in much thinner layers than micron-scale particles.

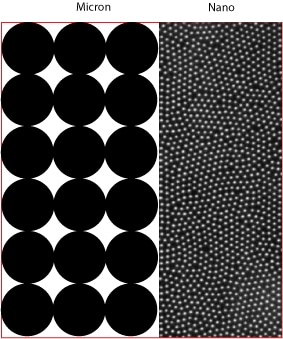

This is not opinion, but based on the scientific law of compaction, which states that the smaller the size of an object, the more densely it can be arranged in thinner layers. Bigger objects cannot be compacted as tightly and therefore have gaps between them. Kids that have built sand castles have known this rule for years. Fig. 1 is an illustration of the law of compaction. The black dots on the left represent micron particles and the white areas represent the gaps between them. On the right, the nano-particles are more compact and there is far less space visible between them. When these principals are applied to sunblock, the white spaces on the left represent large gaps through which UV rays can penetrate. In the nano-zinc-oxide illustration, there are much smaller gaps, tighter compaction and much denser coverage.

When I am in front of people, I often use this analogy: imagine a red carpet covered with big white rocks. Because the rocks are so big, there are gaps between them and you can see the red carpet underneath. Next, envision the same red carpet, only this time covered with white sand. The red carpet in the second example is not visible because the gaps between the grains of sand are so small. In the case of sunscreens that are intended to provide a physical barrier between the skin and the sun, the gaps between micron-scale zinc-oxide particles represent dangerous breaches in the protective barrier, through which UV radiation can very easily penetrate the skin.

More of the science of compaction dynamics can be viewed at the Group for Research and Applications in Statistical Physics (GRASP) website. In our discussions with our research affiliates, it has become clear that the law of compaction is directly relevant and portable to UV protection. The GRASP research and other studies validate that smaller, nano-scale particles enable the formulation of a zinc-oxide physical block that is more monolithic and has a tighter pattern. Further, during application of the sunblock on the skin, the nearly identical nano-particles self-assemble in a much thinner, more compact pattern than would be possible with larger, less uniform micron-scale particles. In other words, the nano-scale zinc-oxide formulation applies more evenly on the skin and in a tighter, denser pattern that ensures the most even, complete and impervious skin coverage possible. The more even and dense the particle array is, the greater the UV protection. Again simple physics that you would learn from Bill Nye the Science Guy!

Issue #2: How can sunscreen manufacturers claim they are effective while also claiming they do not use nano?

Answer: They are really using nano and either don’t know it or don’t care. If it goes on clear, it is nano.

Some sunblock suppliers claim they are not using nano-zinc-oxide, yet still claim to have the same transparency and effectiveness as nano-scale solutions even though they are using larger-scale particles, which of course is impossible because of the intra-particle gaps inherent with the larger particles. The answer to the riddle may lie in how, and with what equipment, the sunblock manufacturer’s zinc-oxide supplier is measuring the particles.

In my lab I have collected samples of all forms of zinc-oxide particles and zinc-oxide dispersions from most, if not all, manufacturers of zinc-oxide. I have zinc-oxide samples used for personal care products and even samples used to make varnishes to protect wood finishes. Using Transmission Electron Microscope (TEM) technology, I can peer into the world of nanotechnology and reveal the structure of a wide variety of zinc-oxide particles. So, you can say that the TEM is a sort of lie detector on a nano-scale, that reveals the truth about zinc-oxide particle size and structure.

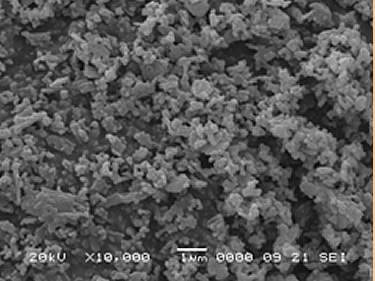

When we looked at two major providers of large-particle zinc-oxide, we noticed that the particles in the oil dispersion very closely resembled our own nano-zinc-oxide particles. Upon closer inspection with high-resolution microscopes, however, the alleged micron-scale particles were actually an agglomeration of smaller, nano-scale particles. To the left (Fig. 2) is a picture of an agglomeration of zinc-oxide particles. As you can see, they are clumpy and jagged-looking. I believe this agglomeration holds the key to how some core ingredient manufacturers of zinc-oxide believe they can claim their particles are not nano-scale. Incidentally, some of these particles are among the finest nano-zinc-oxide in the world.

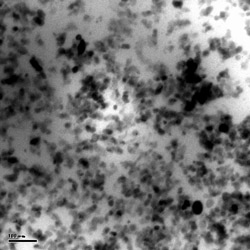

Looking at the same agglomeration after dispersion into the final sunscreen products, the agglomeration would have seemed to have disappeared and broken up into separate nano particles. 80+% of the particles in the nano graph to the right are ~20nm See figure 3

When I first engaged with zinc-oxide manufacturers, I could not figure out why they would not sell me just the particles in powder form — they said I had to buy the particles dispersed in oil. And then as I began to study the particles, I could not understand why the manufacturers would go to the effort to create some of the most perfectly shaped nano-particles in the world, only to wad them together to create micron-sized particles.

Perhaps it is marketing interpreting science to enhance their story and tell customers what they think they want to hear? Please keep in mind as you read on that there is an old adage that says, “liars figure and figures lie.”

Here is what I theorize: manufacturers first measure the zinc-oxide particle size using a Malvern Mastersizer particle size analyzer. This is a device that is nowhere near as precise as a TEM or even a lower-resolution scanning electron microscope (SEM), and, in fact, is not really suited to measuring nano-scale objects. Further corrupting the measurement process, manufacturers create a sample preparation in such a way that the dispersion becomes unstable and leads to particle agglomeration and a resulting larger object to be measured than the original, single particles. It also is important to understand that, in the process of manufacturing, it is necessary to wash the zinc-oxide particles to remove salts. When the particles are dried, they tend to agglomerate. I suspect that manufacturers use a technique called spray drying that tends to increase, rather than decrease, the agglomeration. Depending on when in the agglomeration and subsequent dispersion process the actual measurement is made, it is possible to get virtually any desired result.

When measured with a Malvern Mastersizer, the aforementioned particle agglomerations clustering was, indeed, 1 micron in size, as advertised by the manufacturer. After this first measurement, the manufacturer disperses the agglomerate in oil and the agglomerate breaks up into nano-particles. We know this is true because we examined and measured the particles using a TEM. (Incidentally, a TEM is much more powerful than an SEM. One of the three TEMs that we have access to is able to resolve 0.5 nm objects). So, what I think they are doing is measuring the agglomeration, knowing full well that, in the oil dispersion, the agglomeration will separate back into nano-particles. (see Fig 3) They are careful to say, simply, that they “measured” the particle — and not that they measured the particle prior to it being dispersed in oil back to its original nano-size.

In layman’s terms, it is sort of like making homemade oatmeal. You put the oats in the water and cook them until they become one huge ball of mush. That is the agglomerated mass I describe earlier. Then when you serve it, you put some milk on it and it separates into the single oats. You see the agglomeration and the kids see breakfast.

Another maker seems to follow a similar process. They mention in their brochure that they have no nano-particles, but they include the disclaimer, “when measured by generally accepted methods.” That makes one wonder what they might be hiding during any potential agglomeration and dispersion process.

Yet another manufacturer shows an image of what look like two identical nano-particles, and claims that their particle is more transparent. The rub? They are both identical nano-particles…not one micron-scale and one nano-scale particle.

Clearly, makers of the sunscreens using these micronized micron, macro or whatchacallit type of particle may or may not know or understand what I just described. But they should. I cannot excuse this “ignorance is bliss” way of thinking because it is our responsibility as sunscreen and sunblock manufacturers to find out everything about ingredients, component ingredients and the effects of various processes on our ingredients. I truly suspect that many manufacturers already know that they are “bending” truth and science, which also makes me a skeptical about their motives.

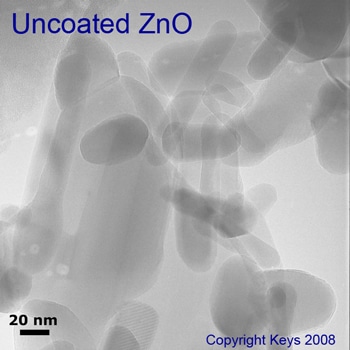

We, on the other hand, are proud to share the data about our Solar Rx moisturizing sunblock. In Fig. 4, for example, are the nano-particles we use. As you can see, they are very small, separate particles. They are between 10 to 40 nanometers in size with most being around 25 nanometers. They have smooth even shapes. They are not stuck together like a wad of oatmeal.

The part of this that baffles me is why some sunscreen makers would not stand up for the technology they are using. Maybe it is motive-driven science? Do you think?

Nevertheless, I guess all is good in the end. Many sunscreens advertised as micron-scale that people are using are most likely effective and protecting them because they are probably really using nano-zinc-oxide, after all.

What are the next steps for us in our quest for the nano-grail? TEM images of all those sunscreens that are advertised as “non-nano.” We are also continuing to research safety and new sciences. Maybe an episode of “Myth Busters.”

Total Sun Protection

As usual, I can’t leave a discussion of sun protection without again saying that, if you want to minimize your risk of skin cancer and implement the most powerful ant-aging tool available, avoid the sun! If you want to stay young-looking beyond your chronological years and you want to protect yourself from developing skin cancer, avoid the sun.

You have heard us say time and again, cover up! Wear UVA rated protective clothing. Wear a UV-rated hat with a 5-inch brim. Wear UVA-rated sunglasses. Apply a broad-spectrum, nano-zinc-oxide-based sunblock to exposed skin like the face, neck and hands. Avoid the sun between 10 a.m. and 5 p.m. Know the UV index where you are, and cover up! OK, lecture over! Read Wendy’s article called Solar Flare for more convincing that leathered skin is plain ugly!